Plek

the optimum in tone and playability

Plek

the optimum in tone and playability

Plek Service at 13th Street Guitars

Plek is almost like an MRI machine and a CNC Robot in one. Plek scans your instrument fretboard and strings while tuned up to pitch. It gives us a very detailed look at what is going on and what can be done to make your guitar, bass, etc... play the best it possibly can.

This computer controlled device scans instruments under actual playing conditions - strung and tuned to pitch - and performs all functions around that data. This is a major breakthrough, as this work was done manually without strings tuned up in the past. This is much more accurate than a jig that simulates string tension, as well.

We had experience with fret dressing and setting up thousands of instruments by hand. With Plek, 13th Street Guitars can deliver even better work than we could ever imagine. We were skeptical of this new technology, like many people are, but once we really came to understand the measurements and processes it's capable of - We are true believers. Plek makes us better than we were, and we were already very good at what we do. We have processed thousands of guitars since getting the machine. The results have been fantastic. We are so spoiled by it, we don't want to play anything that hasn't been Plek'd.

Plek Processes in greater detail

We use a Plek scan to see if the guitar needs the frets dressed, or in less common cases, a partial or complete refret. The plek scan (pictured at right) shows exact fret heights and projects post-dress results.

We then perform a "Virtual Fret Dress" which allows us to project exactly what will happen when the frets are cut. In this manner, we can alleviate whatever issues the guitar has, as well as adjust it for the specific style of the player. Each fret dress is tailored to the action we set. String size, scale, nut height, etc... is all taken into account. The frets are adjusted to each string - as larger strings need more relief and skinnier strings require less.

A great benefit of the Plek process is that we preserve as much fret as we can. This keeps them at their highest possible level. (or we can lower them if you like) Some techs will grind half the frets off a guitar unnecessarily when performing a fret dress. While some guitars will require that, most do not. It's wasteful and it sends the guitar down the road to refretting much sooner. The accuracy of Plek allows us to determine exactly what is required to cut.

We have some custom options that we take advantage of on most guitars. We put on just the right amount of fall-away on the higher frets to make it play great. If you look at your last fret and see wear marks on it - but you never play there - the strings are hitting that last fret or two while you're playing lower notes down the neck. Fall-away (or fall-off) helps prevent this by gradually trimming fret heights slightly lower up in the highest notes. This allows more space for the string to swing without contacting and killing sustain. Very low action can be attained with incredible clarity of tone.

Another option is compound radius. We can grind a little into the tops of the existing frets on many guitars. Big bends just ring out all the way up. You keep that vintage feel but get shredder-like performance on the high notes. This is an option on many new guitars and necks. We offer this on existing guitars.

Once the virtual fret dress is complete, the instrument is prepped in the cradle for processing. The strings are slacked and tucked around the back of the neck. Plek will scan the neck again to see how the shape has changed without string tension on it. Then it will process the frets according to our programming. When this is complete, we tune it back up to pitch for one more scan - just to make sure everything is perfect.

The final steps are performed on the bench. This is where we cut the nut slots, polish the frets, and make bridge/saddle adjustments for intonation and the action we planned for in the virtual fret dress. (and all the other little setup details)

Combining this great tool with our skills from thousands of fret dresses and setups makes for some amazing playing guitars. If you want to get a feel for it, come on down and try some of our guitars and basses that have been plek'd right here at 13th Street Guitars.

A Plek Scan is just $25. This fee will be applied to the total cost if you decide to have any plek work done on that instrument at that time. Total cost of a Plek Fret Dress & Setup is $230 (including the scan and complete setup)

We are also using Plek as an integral part of our refretting process. We remove the frets and actually scan the fretboard itself. Then we have the option to use the Plek to cut the perfect shape right into the wood itself. We have been producing a lot of compound radius boards with perfect relief (bow of the neck) and fall-away built right in. After finishing the fretboard shape, we put in the new frets by hand, bevel, dress the fret ends, etc... Next the guitar goes back in the Plek machine. Since the fretboard and the frets get the same custom shape treatment, the maximum amount of fret height can be maintained. This ensures a long life for the new fret job and the absolute best consistency all the way down the neck.

Plek is available for Electric and Acoustic Guitars and Basses as well as many Ukuleles and Mandolins.

Plek is awesome for planing fretless bass fingerboards. We can use all the same principles that go into the fret work but cut it into the board. We've produced many incredibly great playing fretless intruments in this manner. We also use it add lines to fretless or convert to fretless or back to fretted.

Overhead view of Plek Planing a fingerboard on a Telecaster

Our Plek Machine Location is in-house at 13th Street Guitars in Huntington Beach, CA.

We're in North Orange County just off the 405. It's a short trip south from many parts of Los Angeles. (just below Long Beach)

We have clients that drive from all over the southwest for our services. If traveling, please call us to make arrangements.

We are not accepting shipped instruments for repair work at this time.

Many guitars come into the shop that were Plek'd at the factory. We've seen some of these that still have fret issues. This scan pictured above is an example of a very expensive guitar from a major manufacturer. It has high frets in prime playing areas. The customer complained of it being buzzy and some notes hardly ringing at all. (mostly on the 4th fret, where the 5th fret is so high the string is hitting it) So while this guitar was Plek'd at the factory, it unfortunately needed work later on. Who knows what environments it passed through before getting to the customer. Hot or cold, high or low humidity, getting banged around in shipping? We Plek the guitar as it is and dial it in for perfect playability. It’s not a cookie-cutter process and each guitar is unique.

Luthiers & Custom Builders

Are you a custom guitar builder and would like to use Plek on instruments you will be reselling? It costs an awful lot of money to buy a machine, so many boutique builders can't justify the cost. 13th Street Guitars can help you with that. We have the Plek Station and are willing to do piece-work to provide your guitars or basses with the services you want.

Fingerboard shaping - Custom compound radius, fall-away cut right into the board at super high accuracy, relief set per string

Fret slot cutting - optional pocket fret slots (natural binding) and just about any scale length

Nut pocket cutting - to fit whichever type of nut you need

Nut carving - shape and slot a nut blank with custom string spacing, slot angles and heights, splay angles

Fret dressing - after you fret it, we can fine tune the fret work as you desire

Inlay Engraving - We can cut the inlay into the fretboard during processing or after frets are installed

Contact us for pricing and project inquiries. We're happy to work with you.

Get Plek'd!

the optimum in tone and playability

Get Plek'd!

the optimum in tone and playability

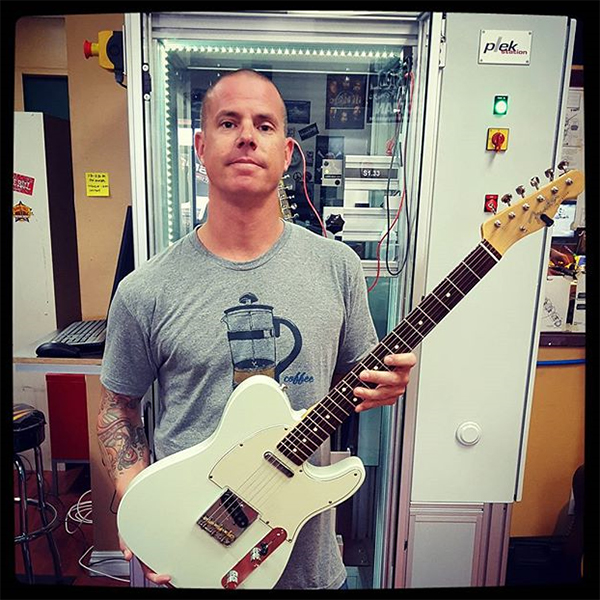

Here's some of the notable players who have had their instruments Plek'd at 13th Street Guitars:

Doug Wimbish - Bass Legend - Living Colour, The Sugar Hill Gang, Mick Jagger, James Brown, Seal, Mos Def, etc

Brooks Wackerman - Avenged Sevenfold, Solo Artist

Scott Holiday - Rival Sons, with his Kauer Banshee

Randy Bradbury - Pennywise

Noodles - The Offspring

CJ Ramone - The Ramones

Wayne Sermon - Imagine Dragons

Joe Escalante - The Vandals - Sweet and Tender Hooligans

Steve Soto RIP - Adolescents, Agent Orange, Manic Hispanic

Rose Deocampo - Cowgirls From Hell (all girl Pantera Tribute), Infinite Death

Diego Verdusco - Ill Nino

MLB Slugger & Guitarist Mark Trumbo

Bryan Beller - Bass for Joe Satriani, Steve Vai, Dethklok, The Aristocrats (with Guthrie Govan)

Nils Akkerman - founding member of The Vandals, Anarchy Taco

Dave Nassie - Kip Moore, No Use for a Name, Bleeding Through

Dan Root - Adolescents - CJ Ramone

Flashback Heart Attack (80's Tribute)

Jordan Griffin - Them Evils

Trevor Green - Cole Clark Artist, World Touring Solo Performer

Christy Lichtenstein - Spector Artist, Studio Session Bassist

Call us for an appointment and see what we can do for you!